Finally, the NFL Draft has finally kicked off in Detroit.The first round is officially in the books, and each of...

Bethesda's upcoming next-gen update for Fallout 4 is riddled with issues across PlayStation, Xbox, and PC.The next version was finally...

Beijing (AFP) - US Secretary of State Anthony Blinken met on Friday with Chinese President Xi Jinping and senior Chinese...

After April 26, 2024, 6:50 am Jorge Quiroga, former president of Bolivia. Photo: NTN24 Former Bolivian President Jorge Quiroga has...

Including food and energy, the PCE price measure for all items rose 2.7%, compared to estimates of 2.6%.On a monthly...

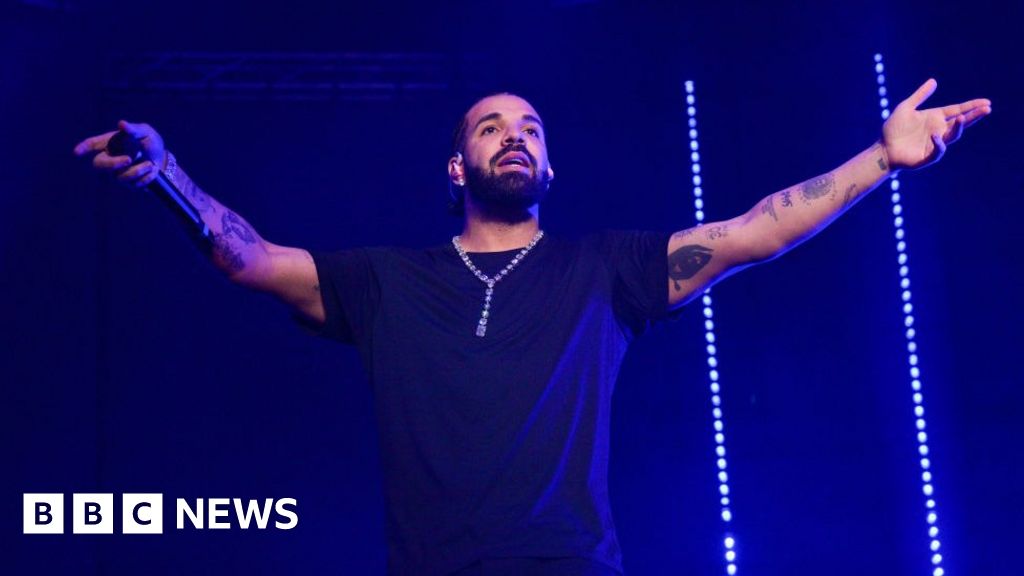

By Vicky Wong and Bonnie McLarenBBC News2 hours agoImage source, Getty ImagesComment on the photo, Drake has removed a track...

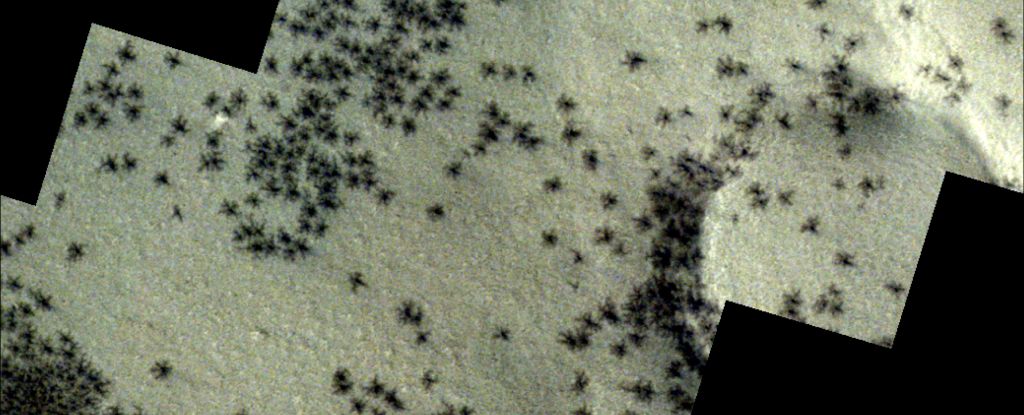

There may not be any insects on Mars, but new images taken by a spacecraft orbiting Mars have revealed a...

Amarius Mims has started just eight games in his college career, but the talented offensive tackle has a high enough...

Palestinian officials in Gaza on Thursday raised the number of bodies discovered in a mass grave on the grounds of...

NEW YORK.- Hundreds of supporters protest Israel They protested outside this Thursday Columbia Universityin the north ManhattanIt has been occupied...